#construction sites

Explore tagged Tumblr posts

Text

New Yorkers love to peer through holes in the walls surrounding construction sites to watch the activity inside. In 1959 some contractor that was putting up a new office building came up with the idea of not only enlarging the holes, but providing 15 phones giving a running account of the work through a recorded message.

Photo: Everett on Demand

#vintage New York#1950s#construction#onlookers#construction sites#building#vintage NYC#gawkers#building site

205 notes

·

View notes

Text

Construction and wires, somewhere in Spanaway or maybe Elk Plain, WA - Summer 2024

11 notes

·

View notes

Text

I love harvesting machines like fuck yeah dude those carrots are going to heaven

#Woof#Evidence that I've remained largely unchanged since age 4 when I watched that educational farm VHS over and over and begged to be taken to#construction sites#I love a big moving machine

19 notes

·

View notes

Text

A fence, concrete and the underside of a tower crane.

Black and white photography.

#building site#building sites#construction#construction site#construction sites#photography#photo#photos#picture#pictures#image#images#a photo#a picture#an image#photograph#photographs#a photograph#construction photo#construction pictures#building site photo#black and white#black and white photo#black and white photos#black and white photograph#black and white photographs#black and white picture#black and white pictures#black and white image#black and white images

2 notes

·

View notes

Video

youtube

The best square tube forming equipment for construction sites, simple an...

0 notes

Text

5 Best Autonomous Robots for Construction Sites

New Post has been published on https://thedigitalinsider.com/5-best-autonomous-robots-for-construction-sites/

5 Best Autonomous Robots for Construction Sites

The construction industry is at a fascinating crossroads where robotics and automation are reshaping how we build our world. As the global construction robots market surges toward $3.5 billion by 2030, these machines are fundamentally transforming job site safety and capabilities. From autonomous pile drivers constructing massive solar farms to robotic assistants tying rebar with superhuman precision, these groundbreaking autonomous robots show us how automation is tackling construction’s most challenging tasks.

When it comes to transforming construction sites through automation, Dusty Robotics’ FieldPrinter system is one of the best out there. It helps bridge the gap between digital building plans and physical execution, tackling core challenges like labor shortages and tight project timelines head-on.

The technical magic happens through a remarkably precise automation system. The FieldPrinter processes building information models with an impressive 1/16-inch accuracy at 600 DPI. This is the kind of precision that transforms how trades coordinate on site. By integrating directly with industry standards like Autodesk Revit and AutoCAD, the system ensures that digital models translate perfectly into physical markings, creating a seamless flow from design to construction.

The real power of this system shines through in its practical impact. A single operator can mark up to 15,000 square feet per day, dramatically accelerating traditional layout timelines. For example, Skanska USA’s medical office building project demonstrates the tangible results: a $3 million cost reduction and a three-month acceleration in project timeline through automated multi-trade layout.

The platform’s comprehensive approach combines precision hardware with sophisticated software integration. Through its collaborative portal, iPad app, and direct BIM (Building Information Modeling) connectivity, the FieldPrinter creates a unified system to streamline communication between all project stakeholders, ensuring everyone works from the same exact specifications.

Key features

AI-driven layout system with BIM model integration

Multi-trade coordination framework processing complex spatial data

Automated marking system achieving 1/16″ accuracy

High-speed processing capabilities covering 15,000 sq ft daily

Collaborative portal architecture supporting unlimited project access

Visit Dusty Robotics →

When exploring construction robotics, DEEP Robotics’ quadruped systems are fascinating examples of how embodied AI can transform dangerous and repetitive tasks. These sophisticated robotic platforms are intelligent systems that bring new capabilities to some of construction’s most challenging environments.

The technical sophistication of these quadruped robots reveals itself in their remarkable adaptability. Through a combination of advanced AI and precision engineering, these platforms navigate complex construction environments with agility. Their integrated sensor systems and GPS capabilities enable high-precision mapping and surveying tasks, while sophisticated obstacle avoidance algorithms ensure smooth operation in cluttered construction sites.

What makes these robots particularly compelling is their practical application in construction surveying and mapping. The system’s AI-driven algorithms handle more than just basic navigation – they actively process complex environmental data to support precise surveying operations. This automated approach improved traditional mapping tasks, bringing new levels of accuracy and efficiency to construction site documentation.

The platform’s versatility extends beyond basic mobility. Through remote operation capabilities and intelligent algorithms, these quadruped robots tackle challenging surveying environments that would typically pose significant risks to human workers. Their ability to combine AI processing with excellent obstacle avoidance creates a system that enhances human capabilities through consistent, precise execution of complex tasks.

Key features

Advanced quadruped mobility system with all-terrain capabilities

AI-powered obstacle avoidance for complex site navigation

High-precision mapping and surveying functionality

Remote operation framework for hazardous environments

Integrated sensor suite for comprehensive data collection

Visit DEEP Robotics →

Solar farm construction reveals one of the most impressive breakthroughs in construction automation – Built Robotics’ RPD 35 autonomous pile driving system. This remarkable machine, working in tandem with the RPS 25 stabilizer, transforms the traditionally labor-intensive process of installing solar panel foundations into an impressive feat of robotic precision.

The technical capabilities of this system are nothing short of extraordinary. Picture a robot that achieves sub-centimeter accuracy through a sophisticated array of RTK GPS, IMUs, and laser rangefinders. But what really makes it unique is its raw efficiency – driving a new pile every 73 seconds, the RPD 35 operates three to five times faster than traditional methods. With a capacity to carry 224 piles and install 300 per day with just a two-person team, it is an entirely new way for how we approach large-scale solar construction.

Safety takes center stage in the system’s design through an intricate 8-layer security framework. The robot maintains constant vigilance with 360° smart cameras and AI-powered vision systems, while wireless emergency stops and 24/7 remote monitoring provide additional layers of protection. This comprehensive approach dramatically reduces worker exposure to noise, extreme weather, and the inherent risks of manual pile driving.

The impact on project economics is equally impressive. Consider a 250 MW solar park requiring 100,000 piles – the RPD 35’s speed and precision translate into substantial time and cost savings. By minimizing rework through precise placement and providing automatic “as-built” documentation, the system creates a new standard for construction efficiency while addressing the persistent challenges of labor shortages in the industry.

Key features

Autonomous pile driving system with 73-second cycle time

Sub-centimeter accuracy through advanced sensor integration

224-pile carrying capacity for continuous operation

8-layer safety system with AI vision monitoring

Automatic documentation and quality control framework

Visit Built Robotics →

Precision can make or break a construction project, and Civ Robotics stands out with an impressive suite of autonomous robots. Their flagship products – the CivDot, CivDot+, and CivDot Mini – each bring unique capabilities that tackle different aspects of the layout challenge.

Let’s start with raw performance: the CivDot is a rugged powerhouse, capable of marking an astounding 3,000 points or 16 miles of lines daily with 1/10′ accuracy. This 4WD rover works fast and smart, using a Trimble R780 GNSS receiver and IMU-based tilt correction to maintain precision even on rough terrain. For projects demanding even higher precision, the CivDot+ steps in with remarkable 3/100′ (8mm) accuracy, though it trades some speed for this precision, marking up to 1,200 coordinates per day.

The real one to pay attention to here is the CivDot Mini, specifically engineered for line striping tasks. This specialized robot can mark up to 17 miles of both solid and dashed lines per day with sub-inch accuracy – a capability that transforms tasks like parking lot striping from multi-day projects into single-shift accomplishments. Just check out DPR Construction, who saw a four-day layout job shrink to just four hours using this system.

What makes these robots truly innovative is their accessibility. Unlike complex construction equipment requiring specialized certification, these machines welcome operators of all experience levels. They come pre-loaded with CivPlan software for straightforward mission planning and data management, while providing detailed reporting features that track every marked coordinate with timestamps and elevation data.

Key features

High-speed layout capability marking up to 3,000 points daily

Precision ranging from 1/10′ to 3/100′ accuracy

Integrated GNSS and IMU systems for terrain adaptation

User-friendly interface requiring minimal training

Comprehensive data logging and reporting system

Visit Civ Robotics →

When it comes to rebar installation, TyBOT from Advanced Construction Robotics is an excellent choice in construction automation. This tireless robot tackles one of construction’s most physically demanding tasks – tying rebar intersections – with a precision and speed that is changing how sites approach concrete structure development.

The technical capabilities of TyBOT showcase impressive engineering. Without any need for pre-programming or BIM input, this autonomous system achieves a 99% accuracy rate while maintaining an active tie rate exceeding 1,200 ties per hour. Each 15-pound spool of wire enables approximately 3,000 ties, allowing for extended operation. The system’s adaptability is noticeable through its ability to handle various rebar types and grid spacings, while managing cross-slopes up to 30 degrees.

What makes TyBOT particularly powerful is its operational simplicity. Within just two hours of arrival on site, the system can begin operations, requiring minimal setup time. The robot works through an intuitive control interface, providing real-time feedback and troubleshooting guidance. Powered by a 7,000-watt generator, it maintains consistent operation for 10-hour shifts without refueling.

Key features

Autonomous rebar tying with 1,200+ ties per hour

99% accuracy rate without pre-programming

Adaptable operation across various rebar configurations

Real-time monitoring through cloud-based platform

Extended operation with 3,000-tie wire capacity

Visit TyBOT →

Workers and Robots Constructing Together

As we have explored these pioneering construction robots, one thing becomes clear – the future of construction is increasingly automated, but in ways that enhance rather than replace human capabilities. With the construction robots market growing at an impressive 17% annually, these innovations represent just the beginning of a broader transformation. Each robot we examined, from Dusty’s precise layout systems to TyBOT’s rebar tying, addresses specific industry challenges while pushing the boundaries of what is possible on construction sites. As these technologies continue to advance and new innovations emerge, they will create safer, more efficient construction practices that will shape our built environment for generations to come.

#000#250#Accessibility#ai#AI-powered#Algorithms#app#approach#architecture#attention#automation#autonomous#autonomous robots#Best Of#billion#bridge#Building#Cameras#certification#challenge#Cloud#collaborative#communication#comprehensive#concrete#connectivity#construction#construction sites#continuous#cost savings

0 notes

Text

What are the top safety measures at construction sites?

Develop a Comprehensive Safety Plan A well-structured safety plan is a vital aspect of project planning in construction. It ensures a safe working environment by facilitating operations that protect staff, visitors, and contractors alike.

Implement Risk Management Strategies Construction projects involve various risks that can disrupt schedules, increase costs, and lead to disputes if not addressed. Effective risk management involves identifying, assessing, controlling, and monitoring risks to ensure the project's success.

Define Health and Safety Responsibilities Clearly outline health and safety responsibilities at every level of your organization, not just within HR. Incorporate policies, goals, and action plans to ensure accountability and compliance across the board.

Communicate Your Safety Vision Share your organization’s safety objectives and corporate vision with all stakeholders. Aligning everyone with a unified health and safety strategy is critical for achieving a cohesive safety culture.

Establish and Enforce Accountability Accountability for health and safety applies to everyone, including managers and supervisors. Enforcing this ensures leadership commitment and drives a positive cultural shift toward safer practices.

Provide Multiple Reporting Channels Offer diverse ways for employees to report health and safety concerns confidently. A robust reporting system, supported by a clear chain of command, encourages openness and helps prevent accidents.

Encourage Incident Reporting Foster a culture where employees feel comfortable reporting all incidents and near misses. While there may initially be an increase in reports, it helps identify potential hazards and prevent future incidents.

Conduct Regular Safety Meetings Schedule regular safety meetings—weekly or monthly—and involve employees in leading discussions to boost engagement. Make policies accessible both digitally and in print to enhance understanding and compliance.

Offer Comprehensive Safety Training Show your commitment to employee wellbeing by providing thorough safety training, especially for new hires. This helps instill a strong safety culture from the start.

Lead by Example Managers and supervisors should model safe behaviors, demonstrating their commitment to health and safety. When leadership prioritizes safety, employees are more likely to follow suit, fostering a positive safety culture.

By integrating these practices, construction projects can create a safer work environment, enhance employee confidence, and ensure smooth project execution.

0 notes

Text

Every construction company faces the challenge of cutting costs without compromising efficiency. With tight budgets, project delays, and the constant risk of theft, staying on track can feel like an uphill battle. But what if there was a way to streamline operations, prevent losses, and keep your projects running like clockwork? That’s where RFID technology steps in. This advanced tracking solution has become a game-changer for the construction industry, helping companies stay within budget and improve how they manage their resources.

RFID technology is gaining rapid popularity due to its ability to solve some of the most persistent problems in construction. By Using RFID tags to track inventory in real time to reduce downtime caused by missing equipment, RFID brings precision and efficiency to construction site management. Implementing RFID technology allows for better coordination between workers and materials, reducing delays and minimizing errors. This not only helps to control costs but also keeps projects moving forward smoothly.

Our PCB RFID Tags are highly reliable, durable, with anti-counterfeit technology, and absolutely compatible with high temperatures comparatively. These are also known as smart PCBs with RFID tags. The working remains the same and can be easily deployed for all types of tracking. These tags are so small that they can be easily embedded with electronic equipment like Mobile Phones, LEDs, Computers, and other electronic devices that contain a PCB. Apart from this, these can also be used in consumer goods, medicines, straps and medical equipment, Metallic Molds, Hardware tools, etc. These tags have their own advantages as they need very low space on the PCB, can work easily without an antenna, and can also communicate without a line-of-sight connection possible.

If you have questions about any of our RFID Tags listed below please feel free to contact us.

#RFID Tags#RFID Technology#rfid solutions#Construction Sites#Inventory Management#Asset Tracking#High Temperature PCB Tags#RFID asset Tags#RFID Metal tags

0 notes

Text

HP SitePrint Launches in Australia to Boost Construction Industry Productivity

Today HP Inc announced the availability of HP SitePrint in Australia, following a successful general availability in five regions with a proven track record across North America and Europe. HP SitePrint is a robotic solution that prints the most complex construction site layouts with pinpoint accuracy, empowering construction pros with up to ten times the productivity of traditional chalk-line…

View On WordPress

#advanced robotics#Australia launch#autonomous robots#building layout#CAD integration#cloud tools#construction accuracy#construction challenges#construction efficiency#construction growth#construction innovation#construction management#construction sector#construction sites#construction software#construction solutions#construction technology#digital construction#digital layout tools#erasable inks#global availability#global construction#high productivity#HP Inc#HP robotics#HP SitePrint#interchangeable inks#layout automation#layout precision#obstacle avoidance

1 note

·

View note

Text

Project updates:16-ton Double Girder Overhead Cranes

IntroductionA Look At Manufacturing ProcessSpecific UTILISATION in the Presse Machines Production IndustryHow to Determine the Price of Your Crane ProjectConclusion Introduction Welcome to our latest blog post where we take you behind the scenes on one of our biggest achievements of the year, a remarkable project we undertook for a leading company in the presse machines production industry. In…

View On WordPress

#16-ton overhead crane#construction sites#crane construction#crane design#crane project pricing#crane safety features#double girder overhead crane#heavy machinery#machinery parts#presse machines

0 notes

Text

finally pictures of my high vis dress

#petticoat be peeking smh#artists on tumblr#me oh my#high vis#construction site#fashion#sewing#yellow#green#dress#1950s#1950s style#interesting choosing shots and crops to post to make it less easy to geoguess the pics

1K notes

·

View notes

Text

A black and white photo of a construction site.

#building site#building sites#construction#construction site#construction sites#photography#photo#photos#picture#pictures#image#images#a photo#a picture#an image#photograph#photographs#a photograph#black and white#black and white photo#black and white photos#black and white photograph#black and white photographs#black and white picture#black and white pictures#black and white image#black and white images#blackandwhite

4 notes

·

View notes

Text

Stainless steel plates dealer in Vadodara and Gujarat | tubetrading

TubeTrading is your trusted dealer and supplier of stainless steel plates in Vadodara and across Gujarat. With a commitment to quality and reliability, we provide a wide range of stainless steel plates to meet your needs. Experience excellence with TubeTrading - your one-stop destination for stainless steel plates in Gujarat. Whether you require standard sizes or custom solutions, our experienced team is dedicated to delivering products that meet your specifications while ensuring exceptional service and competitive pricing.

Trust TubeTrading for all your stainless steel plate needs, and let us support your projects with top-tier materials and expertise.

#Stainless steel plates dealer in Vadodara#Stainless steel plates dealer in Gujarat#Stainless steel plates Supplier in Vadodara#Stainless steel plates Supplier in Gujarat#steel industry#steel companies#plumbing industry#construction structure#construction sites

4 notes

·

View notes

Text

I don't remember how i found it but there's this website that lets you make your own safety signs and I showed it to my friends and we made a ton of them. here are some of my favourites

(2 of those friends are @ant-bunny and @dawnpstrat)

#196#r/196#we were talking about seeing if we could actually get one of these put on a sign and just putting it up at some construction site#but thats probably illegal#leave which one was your fav in the tags

6K notes

·

View notes

Text

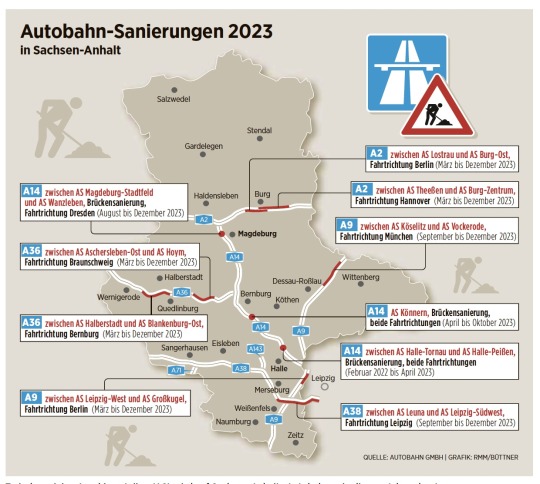

Autobahn-Sanierungen 2023 in Sachsen-Anhalt.

0 notes

Text

Professor Emeritus Jerome Connor, pioneer in structural mechanics, dies at 91

New Post has been published on https://thedigitalinsider.com/professor-emeritus-jerome-connor-pioneer-in-structural-mechanics-dies-at-91/

Professor Emeritus Jerome Connor, pioneer in structural mechanics, dies at 91

Jerome J. Connor ’53, SM ’54, ScD ’59, professor emeritus in the Department of Civil and Environmental Engineering and a member of the MIT faculty since 1959, died on March 31. He was 91 years old.

Over a remarkable career spanning nearly six decades at the Institute, Connor was a prolific scholar and highly respected mentor to several generations of students, many of whom now hold notable positions in academia and industry around the world. His earliest research contributed to the pioneering numerical methods widely used today in structural engineering, such as the finite element method, and was also an early pioneer of the boundary element method. In addition, Connor was the lead proponent of the technical discipline referred to as motion-based design, which is based on limiting displacements against earthquake effects by means of structural control. His leadership role in the application of numerical methods to structural engineering led to significant advances in the numerical simulation of structural and material behavior.

“He was well-known for his intellectual leadership, exceptional dedication to the department, and extraordinary mentoring of students, faculty, and staff,” says Oral Buyukozturk, the George Macomber Professor in Construction Management, who first met Connor when he was an adjunct associate professor at Brown University and was invited to lecture at MIT.

Connor led the department in new teaching and research directions, advocating the importance of materials research and of design education in the civil engineering curriculum. For over 20 years, Connor led the high-performance structures track in the Master of Engineering (MEng) program as faculty advisor. In addition to classroom teaching, he helped MEng students think outside of the box in their design of skyscrapers and bridges. He often accompanied students on weeklong national and international visits to prominent construction sites during MIT’s Independent Activities Period. With his wife Barbara and their family, he regularly entertained students at their summer home on Cape Cod. His dedication and development of the program contributed to its success and recognition at peer institutions as one of the best professional MEng programs in the nation — eagerly sought out by students in structural engineering.

“Connor was truly devoted to our students and he was passionate about the field of structural design. He introduced a number of pedagogical innovations that we still use today, such as semester-long design projects as well as on-site visits to innovative, signature projects together with their design engineers,” says John Ochsendorf, professor of architecture and civil and environmental engineering, who taught with Connor for 10 years and currently leads the structural mechanics and design track of the MEng program.

Adoring mentor and visionary

Connor was a beloved mentor, and from 2007 to 2014 organized and managed MIT undergraduates’ participation in the National Steel Bridge competition. Buyukozturk recalls how “he was always coming up with new and innovative concepts for the competition; several times his team was selected as top in the nation and year after year his students were placed in the top three.”

MIT professor emeritus of civil and environmental engineering Eduardo Kausel, who was a graduate student of Connor’s and then later a colleague, remembers him fondly as an incredible teacher and colleague.

“Jerry was an excellent teacher and I enjoyed taking his advanced computational mechanics class. He was brilliant in computational mechanics and excelled in everything he did,” says Kausel. “As a colleague, he was always kind and had a gentle demeanor; I never saw him getting angry or voicing harsh words. He also had this fantastic ability to mentor students who would go on not only to become very successful as outstanding professionals, but also very wealthy,” Kausel says.

Kausel also remembers Connor’s uncanny ability to look into the future and know where the next big trend occurred in the field. Connor was one of the first researchers to work on the boundary element method in structural engineering. The method is effective in understanding how fluid interacts with structures to ensure its stability, safety, and efficiency. Connor also experimented with artificial intelligence well before it became popular and played a significant role in leading a team of MIT researchers in the development of the STRUDL computer code, which became a highly influential software package for structural analysis and design.

In addition to structural mechanics, he pursued computational fluid mechanics, helping develop early finite element analysis in both the time and frequency domains. His models had applications to offshore engineering, including tidal circulation, and the behavior and design of marine structures for resiliency in withstanding extreme events, including those related to climate change.

Buyukozturk credits the way the department has evolved into what it is today because of Connor’s direction and vision. “Priorities for research change over time, but Jerry set forth a basic roadmap for prioritizing research in computational mechanics, engineering design, and the development of sustainable materials that cut across the entire department in a wider scope,” he says.

Influential wide-ranging career

Born in Dorchester, Massachusetts, on May 19, 1932, Connor attended Boston College High School and received his bachelor’s, master’s, and PhD degrees in civil engineering from MIT. Before he returned to MIT to become a faculty member, he went to work at the Army Materials Lab in Watertown, designing missile systems during the Vietnam War. While on sabbatical in 1983, he served as the dean of the Department of Engineering at Northeastern University and the director of the MIT Sea Grant Program.

Over the span of his career, Connor’s research in structural mechanics attracted the interest of the international community. He spoke at conferences around the world and consulted on many engineering projects, including the Hancock Tower glass crisis, the Twin Towers in New York, and the Parthenon in Greece, among many others. His papers were cited and published among the top engineering journals, and he was honored with numerous awards, including an honorary doctorate from the University of Thessaloniki in Greece. He authored many books on structural engineering, the boundary element method, motion-based design, and computational fluid mechanics. His books have been used in doctoral programs at universities around the world.

Connor led a rich and adventurous life outside of his academic one. Known as “Jerry” to his friends and colleagues, Connor traveled to more than 25 different countries around the world with his wife, Barbara, but was especially fond of the Provence in southern France. Some of his memorable adventures included taking the family by Volkswagen bus throughout Europe during the holiday periods and, during a sabbatical from MIT in 1970, sailing to England on the Queen Elizabeth 2 with his then-young children.

Connor is survived by his wife Barbara, and by his six children: Patricia and her husband Richard, Stephen and his wife Madeline, Brian and his wife Michele, Michael and his wife Christine, Mark and his wife Kathy, Tracy and her husband Maurice, and 14 grandchildren. Gifts in Connor’s memory can be made to Boston College High School.

#Alumni/ae#Analysis#applications#architecture#artificial#Artificial Intelligence#Behavior#Books#box#bridge#buildings#career#change#Children#Civil and environmental engineering#civil engineering#climate#climate change#code#college#Community#competition#computer#computer code#construction#construction sites#Design#development#direction#domains

0 notes